|

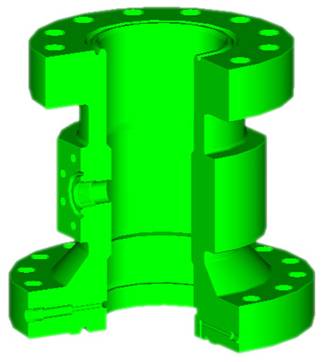

C-22 Casing Heads

C-22 casing heads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Straight Bore Design: Straight Bore Design:

Features a 45°landing shoulder capable of supporting maximum loads.

Prevents test plugs from wedging under pressure.

Manufacturing Standard:

API Spec 6A, PSL2, DD,P U,PR1.

Outlets:

Line Pipe Outlets;

Studded Side Outlets;

Extended Flanged Outlets.

Casing Hanger Compatibility:

Slip-type casing hangers;

Mandrel style casing hangers.

Bottom Connections:

Slip-on weld;

Slip-on weld with O-ring;

Threaded.

Lock-screws:

Casing heads are supplied with 2 lock-screws for wear bushing retention;

Casing heads are supplied with 2 full set of lock-screws for mandrel casing hanger and packoff retention.

C-22 Casing Spools

C-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Straight Bore Design: Straight Bore Design:

Features a 45°landing shoulder capable of supporting maximum loads.

Prevents test plugs from wedging under pressure.

Manufacturing Standard:

API Spec 6A, PSL2, DD,P U,PR1.

Outlets:

Line Pipe Outlets;

Studded Side Outlets;

Extended Flanged Outlets.

Casing Hanger Compatibility:

Slip-type casing hangers;

Mandrel style casing hangers.

Bottom Connections:

For use with PE secondary seal bushing;

For use with HPE secondary seal bushing for high pressure applications.

Lock-screws:

Casing heads are supplied with 2 lock-screws for wear bushing retention;

Casing heads are supplied with 2 full set of lock-screws for mandrel casing hanger and packoff retention.

C-22-EG C-22-EG

Accepting the C-21 and C-22 –type casing hangers, the standard C-22-EG head is an API standard. It eliminates the need for lockdown screws to retain the bowl protectors, creating fewer leak paths. The bottom prep of the casing head can be machined to fit a variety of applications.

The straight bowl design prevents the wedge-locking of bowl protectors, casing hangers, and test plugs, simplifying the installation process. Like all FMC casing heads, the C-22-EG has the option of a detachable base plate, another time-saving feature.

Safety: No need to work under a suspended BOP.

| Casing Head Specifications |

Option of Prep for

Detachable Face Plate |

Line Pipe

Outlets (LPO) |

Studded

Outlets (STDD) |

| 8-5/8" SOW x 9" 2K |

|

Y |

|

| 8-5/8" SOW x 9" 3K |

|

Y |

Y |

| 8-5/8" SOW x 11" 2K |

|

Y |

|

| 8-5/8" SOW x 11" 3K |

|

Y |

Y |

| 8-5/8" SOW x 11" 5K |

Y |

Y |

Y |

| 9-5/8" SOW x 11" 2K |

Y |

Y |

|

| 9-5/8" SOW x 11" 3K |

Y |

Y |

Y |

| 9-5/8" SOW x 11" 5K |

Y |

Y |

Y |

| 10-3/4" SOW x 11" 2K |

Y |

Y |

|

| 10-3/4" SOW x 11" 3K |

Y |

Y |

Y |

| 10-3/4" SOW x 11" 5K |

Y |

Y |

Y |

| 13-3/8" SOW x 13-5/8" 3K |

Y |

Y |

|

| 13-3/8" SOW x 13-5/8" 5K |

Y |

Y |

Y |

| 16" SOW x 16-3/4" 3K |

Y |

Y |

|

| 20" SOW x 20-3/4" 3K |

Y |

Y |

Y |

| 20" SOW x 21-1/4" 2K |

Y |

Y |

|

C-29

With a deeper bowl than a C-22 style casing head, the C-29 accepts the C-29 and C-24-model casing hangers. An API standard, this model is ideal for heavier loads than the C-22- bowl family.

C-29-ET

The C-29-ET is compatible with the C-29 and C-24 casing hangers because it is part of the C-29 product line. With multiple lockdown screws in the top flange, it retains the hanger and can be used to energize the hanger packoff seal. (16" SOW x 16-3/4" 5K & 20" SOW x 21-1/4" 5K)

|